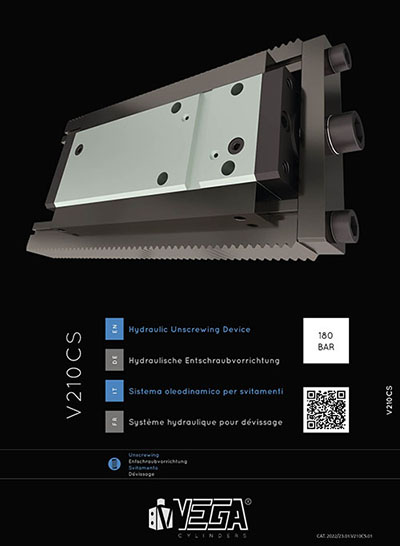

Hydraulic Cylinders for Unscrewing Systems

The V210CS hydraulic cylinders series offers high performances in plastic injection molds featuring unscrewing movements. The standard version includes piston bores from 32 to 50 mm, and strokes from 300 to 500 mm.

These cylinders feature one V220CC block cylinder with 1 or 2 racks on its sides. The cylinder body is made of 7075 aluminum alloy, closed on both ends by 2 steel flanges. The only fixing available for this series is by means of pinned passing-through holes with a key.

Compact Hydraulic Cylinders

The main advantage of these cylinders is their compactness compared to other tie-rod cylinders, especially in plastic injection molds with very little room. The racks—parallel to the cylinder body—offer an enhanced reactivity when it comes to unscrewing movements. A special adjustment screw on the rear head of the cylinder allows for a very precise setting of the cylinder starting point and of the cylinder racks and pinions. These cylinders are compatible with ISO VG 46 mineral oils.

Long-Stroke Hydraulic Cylinders For Pressures Up to 180 Bars

V210CS cylinders feature a special magnet within the cylinder piston, able to generate a very powerful magnetic field. Their stroke can be controlled by means of adjustable electronic sensors, able to read the surrounding magnetic field. Signals can be transferred to the plastic injection machine.

The maximum working temperature of these sensors is 80° C.

The maximum working pressure of these cylinders is 180 bars, and the maximum speed is 0.1 m/s.

Vega Cylinders offers a one-year long warranty for its cylinders, granting full support all over the world. These cylinders can be customized by sending a special project to Vega via e-mail (info@vegacylinders.it).

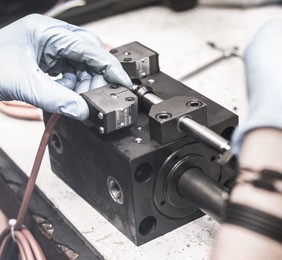

All Vega products are tested before being delivered, in order to offer high-quality cylinders with no oil leakages.